Process NMR Associates has

developed an extension of its 1H NMR analysis of Aloe Vera raw materials

and products analysis. Powder aloe vera raw materials (100x/200x) can

be analyzed directly and juice samples (1x, 5x, 10x, commercial

products) must be freeze dried for this analysis. The whole leaf markers

utilized in this test to indicate the presence of whole leaf material

are iso-citrate and iso-citrate lactone which are formed in the green

leaf part of the aloe plant as part of the citric acid cycle. It is

possible to assign and quantify the following components of an aloe vera

juice or powder:

* aloe vera components: acemannan, glucose, malic acid

* whole leaf markers: isocitrate, iso-citrate lactone, citric acid

* degradation products: lactic acid, acetic acid, fumaric acid, pyruvic acid, formic acid, succinic acid, and ethanol

* adulterants: maltodextrin

* preservatives: sorbate, benzoate

* additives: sucrose, fructose, glycine, flavorants (contain ethanol and propylene glycol)

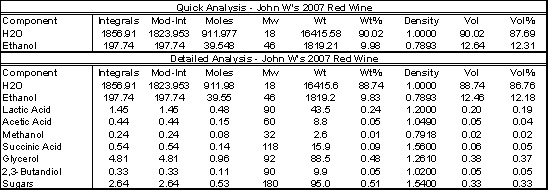

For the components above it is possible to obtain a wt% of that

component in a juice sample – the freeze drying process is then used to

determine the wt% solids in the juice and the dry weight concentrations

of the organic components in the solids.

Currently testing of aloe vera raw materials revolve around acemannan

and whole leaf marker content and the presence of glucose. Process NMR

Associates method can perform this analysis but also tell you the

“quality” of the aloe vera raw material – the absolute concentrations of

degradation products can tell you a lot about the exposure of the raw

material to:

* excessive heat (hydrolyzation of acemannan acetyl groups to acetic acid (vinegar) or formic acid)

* lactobacillus bacteria (found on the skin of the aloe vera plant – these bacteria “eat” malic acid and produce lactic acid)

* enzymatic processes (enzymes found in the aloe vera plant itself can cause degradation to succinic acid or fumaric acid

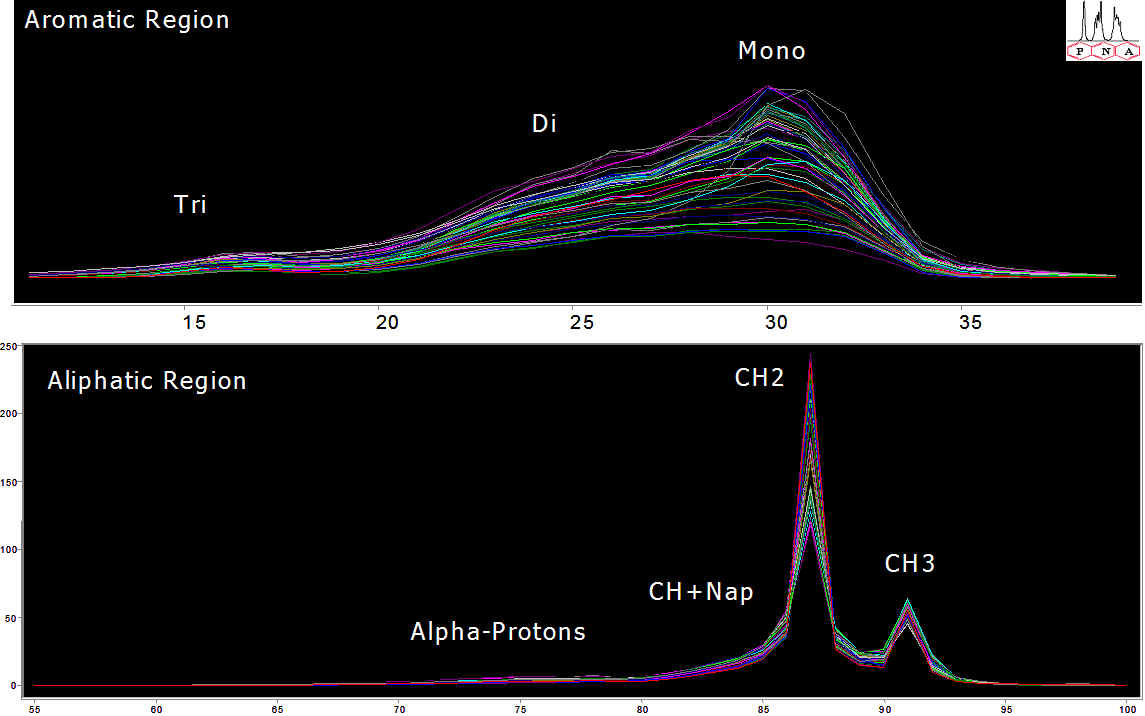

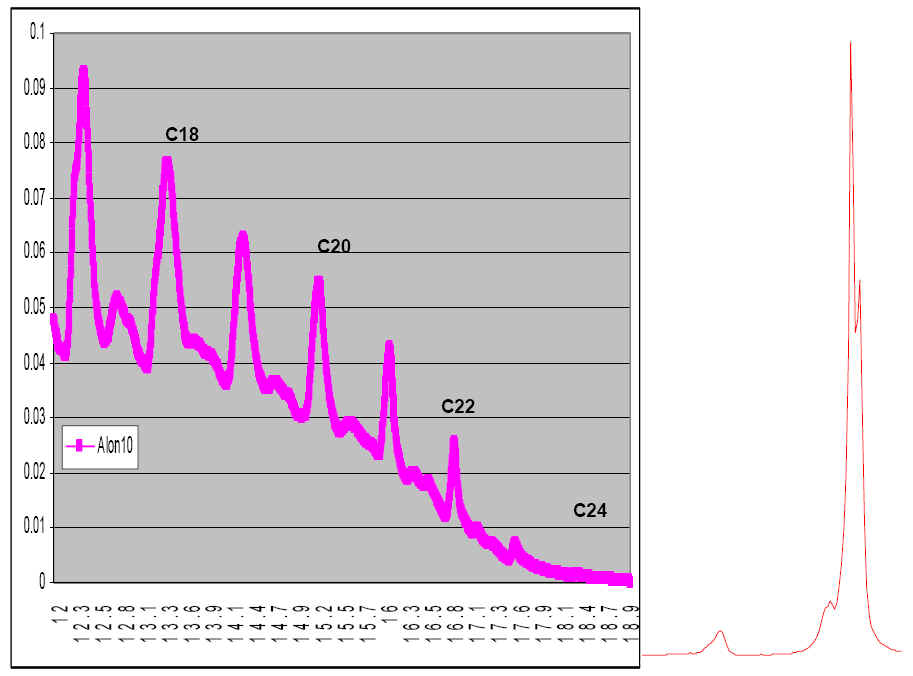

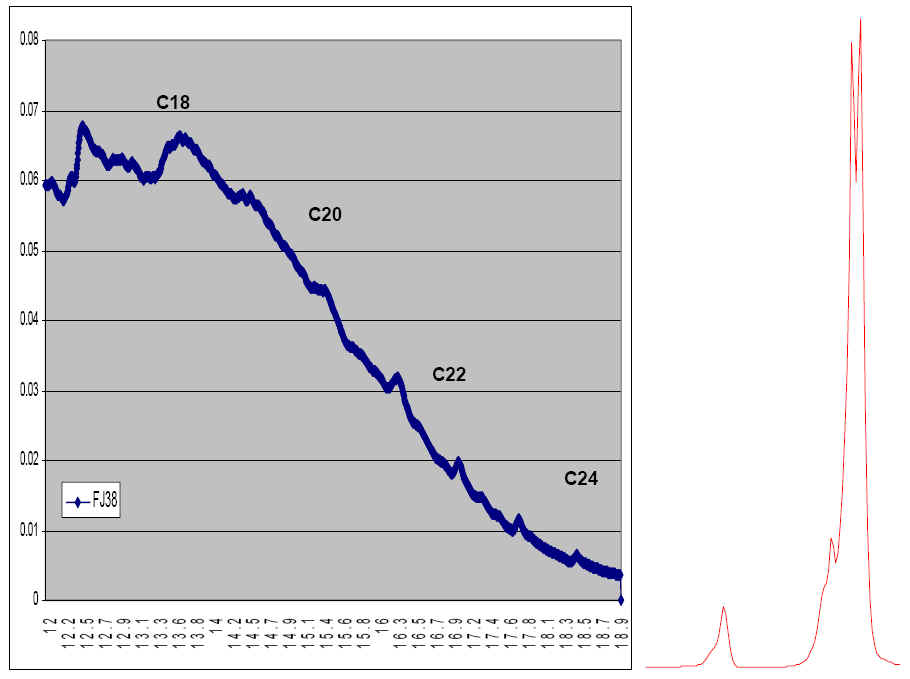

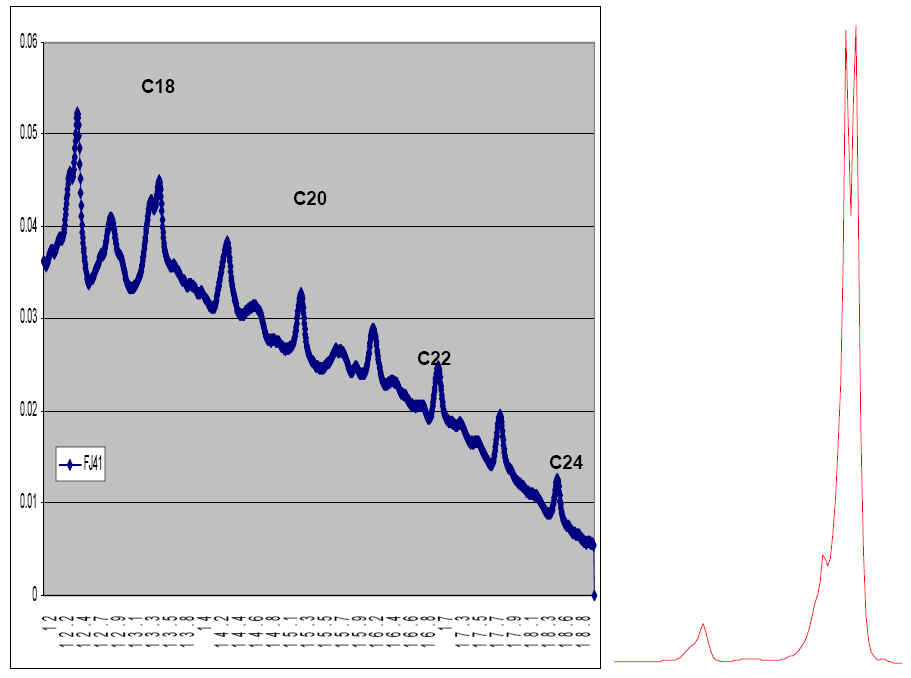

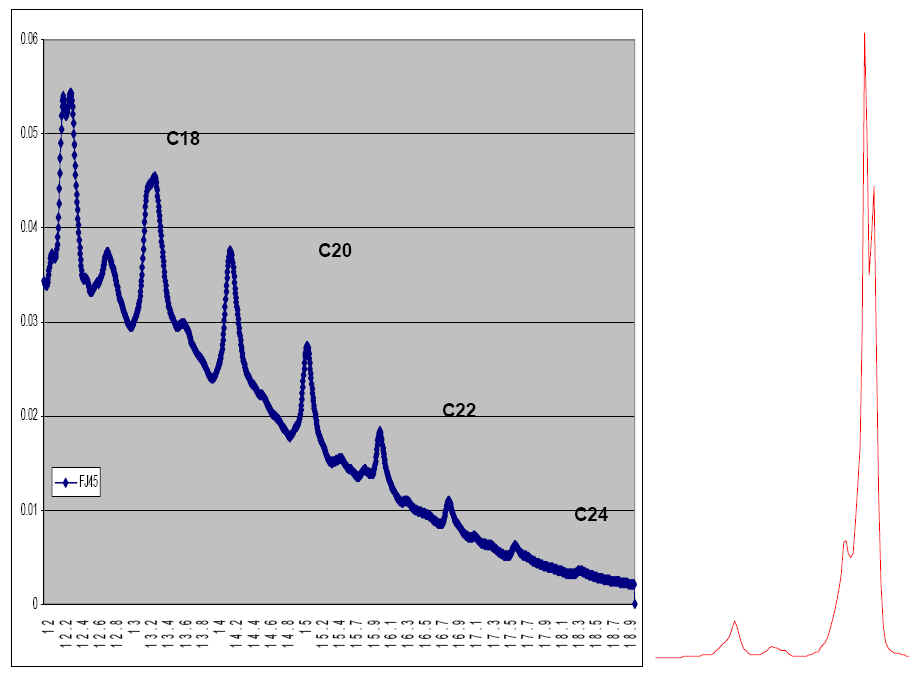

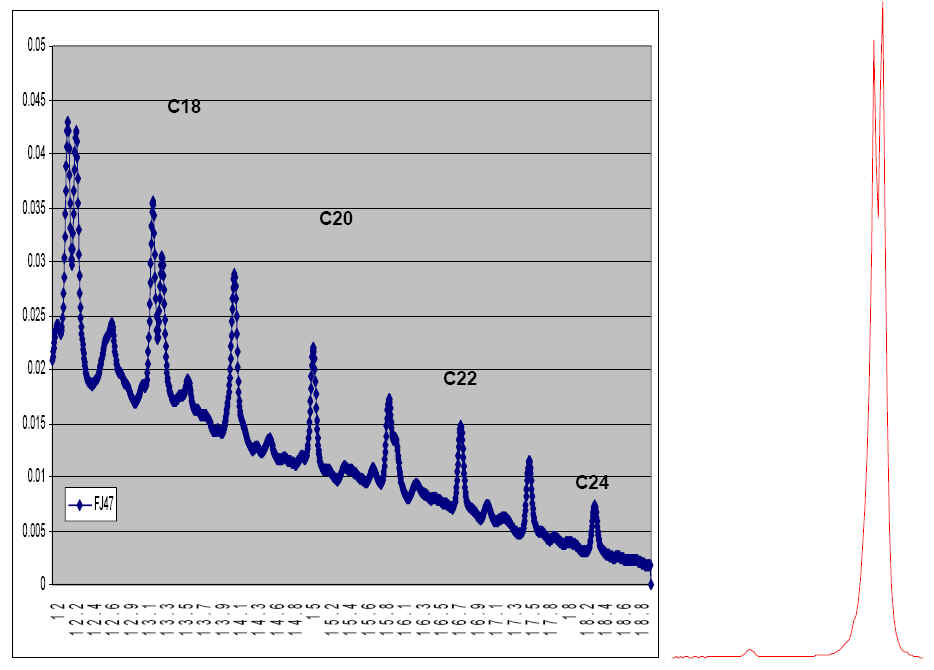

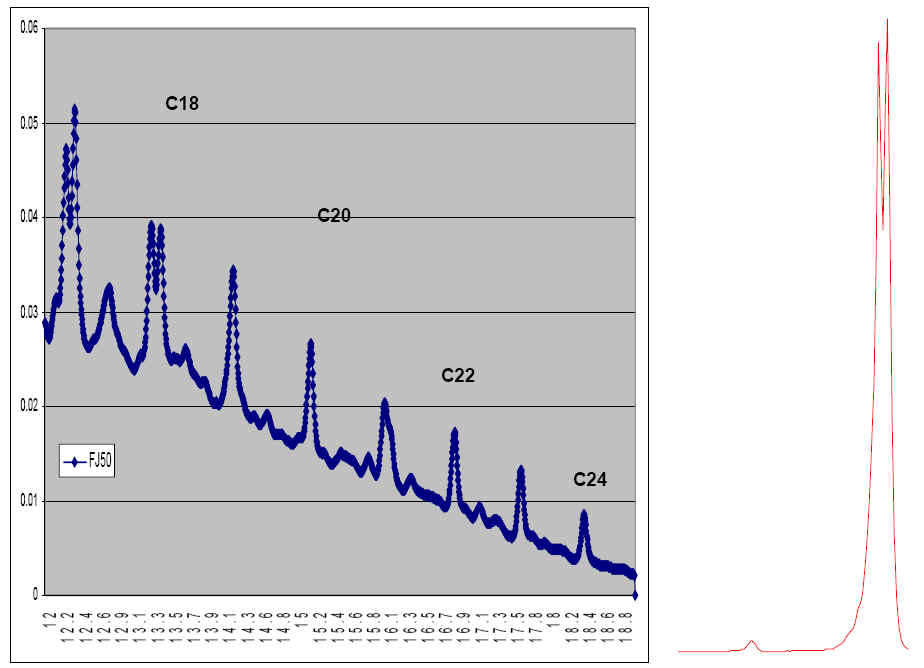

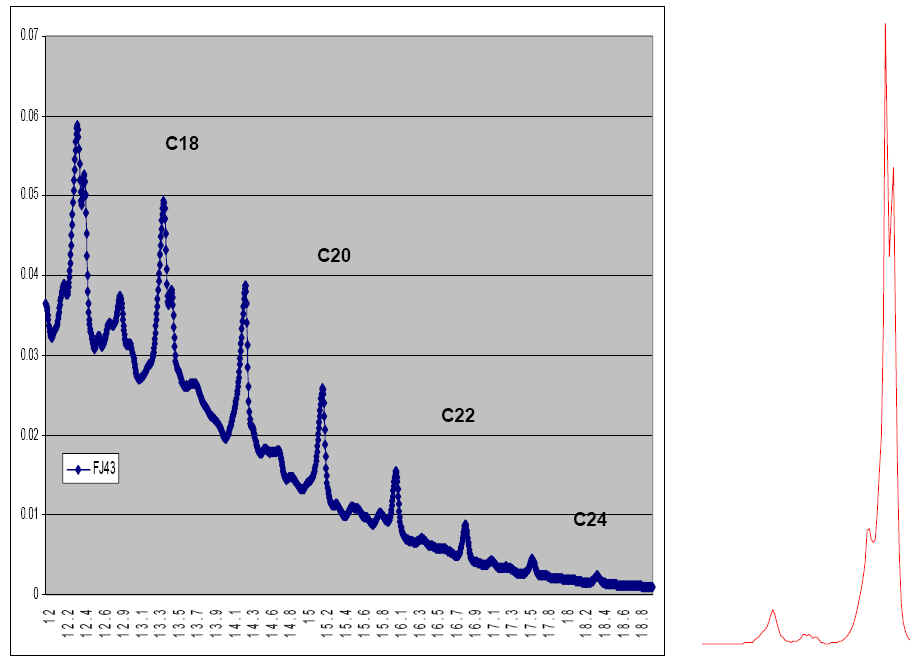

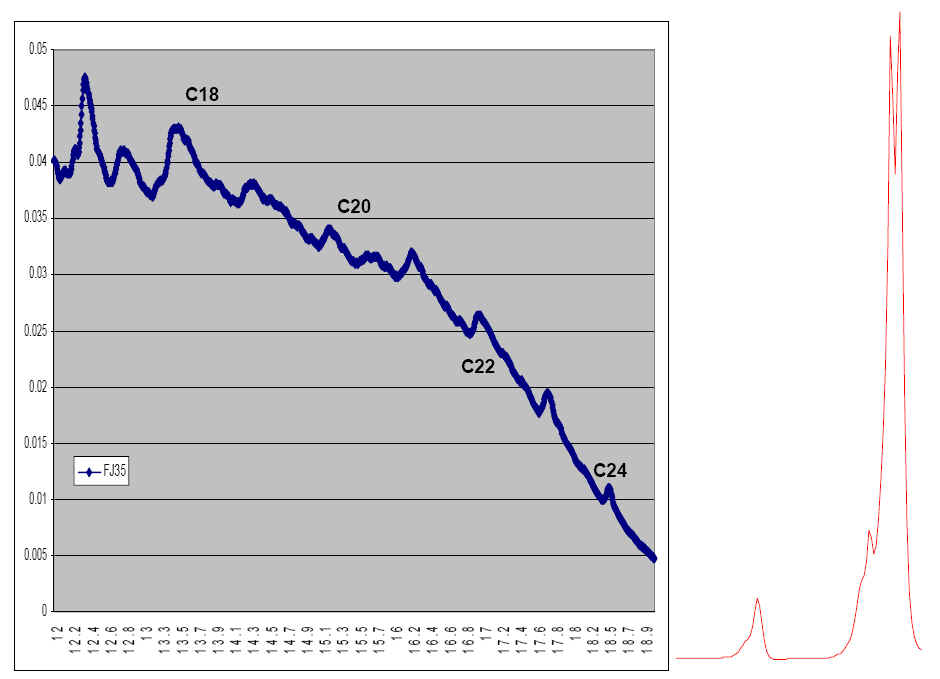

The figure below shows the NMR assignment of a whole leaf juice that

has been freeze dried. From the molar ratios of the various 1H NMR peaks

it is possible to obtain a wt% value for all components by comparison

with a nicotinamide internal standard (spectral range not shown) and

the molecular weight of the component molecule or monomer unit.

1H NMR spectroscopy observes signals from all protons in the sample

simultaneously. Aloe vera components, preservatives, and degradation

products yield peaks at specific chemical shifts which can be integrated

and quantified. Observations are made on the following peaks:

Nicotinamide – Internal NMR Standard: 1) 8.85 ppm, 2) 8.2 ppm (often coincides with formic acid), 3) 7.55 ppm, 4) 8.65 ppm

Glucose – C1 proton for alpha conformation at 5.2 ppm (doublet) and C1 proton for beta conformation at 4.6 ppm (doublet)

Malic Acid – CH at 4.35 ppm (multiplet), CH2 at 2.4-2.8 ppm (multiplet)

Acemannan – CH3 resonances of acemannan acetylation – fingerprint distribution of methyl resonances from 2.0-2.2 ppm

Lactic Acid – CH3 Peak at 1.33 ppm (doublet)

Acetic Acid – CH3 peak at 1.92 ppm (singlet)

Succinic Acid – 2 x CH2 peak at 2.5 ppm (singlet)

Formic Acid – Aldehyde Resonance at 8.2 ppm (singlet)

Ethanol – CH3 peak at 1.18 ppm (triplet)

Pyruvic Acid – CH3 peak at 2.35 ppm (singlet)

Citric Acid – 2 x CH2 resonances at 2.4 to 3.0 ppm (multiplet)

Iso-Citrate (Whole Leaf Marker) – CH at 4.25 ppm (doublet)

Iso-Citrate Lactone (Whole Leaf Marker) – CH at 5.05 ppm (doublet)

Benzoate – ortho-protons (2H) give peaks at 7.8 ppm.

Sorbate – CH3 peak is observed at 1.77 ppm (doublet) olefin protons observed at 5.7, 6.15, &7 ppm.

Fumaric Acid – CH peak at 6.55 ppm (singlet)

Sucrose – C1 proton observed at 5.4 ppm (doublet)

Maltodextrin – qNMR protons observed at 5.4 ppm

Maltodextrin is readily observed and quantified by 1H NMR – in the

figure below is an example of a 100x and a 200x aloe vera gel powder –

the 100x sample contains 50 wt% maltodextrin – the peaks at 5.4 and in

the 3.5-4.0 ppm region are used to quantify the presence of

maltodextrin.

Process NMR Associates is currently the only company providing a

detailed breakdown of the components of aloe vera including quantitation

of the whole leaf markers. Dry weight limits of acemannan, whole leaf

markers, and maltodextrin are required for aloe vera raw material

certification and quality control.

In the food industry it is found that most fruits, beverages, and

dairy products contain a complex mixture of these same organic acid

chemistry components. 1H NMR has a unique advantage in the analysis of

these types of materials as NMR requires very little sample preparation

and the data can be used to unequivocally identify the presence of

single component chemistries and to quantify their presence in a single

15-30 minute analysis. Process NMR Associates are available to develop

NMR based methodologies on any of these types of food systems and would

welcome discussion of this with potential customers. Customers are not

charged for initial consultation and project scoping. These NMR methods

are universally applicable on NMR systems from 200-900 MHz.

If you are

interested please contact

John Edwards (Tel: +1 (203) 744-5905)